Similar Recommendations for Capacitor Cabinet Components

I. Introduction

Capacitor cabinets are essential components in modern electrical systems, playing a crucial role in enhancing power quality and efficiency. These cabinets house various electrical components that work together to improve power factor, reduce energy losses, and stabilize voltage levels. As industries and commercial establishments increasingly rely on efficient energy use, understanding the components of capacitor cabinets and their optimal selection becomes paramount. This article aims to provide recommendations for the essential components used in capacitor cabinets, ensuring that users can make informed decisions for their specific applications.

II. Overview of Capacitor Cabinets

Capacitor cabinets serve a vital function in power factor correction, which is the process of improving the efficiency of electrical systems by reducing the phase difference between voltage and current. A poor power factor can lead to increased energy costs, reduced system capacity, and potential penalties from utility companies. Capacitor cabinets are commonly used in industrial and commercial settings, such as manufacturing plants, data centers, and large commercial buildings, where they help to manage reactive power and enhance overall system performance.

The key components of a capacitor cabinet include capacitors, contactors, fuses, circuit breakers, reactors, and control panels. Each of these components plays a specific role in ensuring the effective operation of the cabinet and the electrical system as a whole.

III. Essential Components of Capacitor Cabinets

A. Capacitors

Capacitors are the heart of any capacitor cabinet, responsible for storing and releasing electrical energy to improve power factor. There are several types of capacitors, including film, ceramic, and electrolytic capacitors.

1. **Types of Capacitors**:

- **Film Capacitors**: Known for their stability and reliability, film capacitors are often used in power factor correction applications due to their low losses and high voltage ratings.

- **Ceramic Capacitors**: These capacitors are typically used in high-frequency applications and are valued for their small size and high capacitance-to-volume ratio.

- **Electrolytic Capacitors**: While they offer high capacitance values, electrolytic capacitors are generally used in applications where size and weight are critical.

2. **Selection Criteria**: When selecting capacitors for a capacitor cabinet, consider factors such as voltage rating, capacitance value, temperature range, and application-specific requirements.

B. Contactors

Contactors are electromechanical switches that control the flow of electricity to the capacitors. They play a crucial role in switching the capacitors on and off based on the system's needs.

1. **Role of Contactors**: Contactors ensure that capacitors are only connected to the system when needed, preventing unnecessary energy consumption and potential damage.

2. **Types of Contactors**: For capacitor cabinets, it is recommended to use contactors designed for capacitive loads, which can handle the inrush currents associated with capacitor switching.

C. Fuses and Circuit Breakers

Protection devices such as fuses and circuit breakers are essential for safeguarding the capacitor cabinet and the electrical system from overloads and short circuits.

1. **Importance of Protection Devices**: These devices prevent damage to the capacitors and other components by interrupting the electrical flow in case of faults.

2. **Recommendations**: It is advisable to use fast-acting fuses or circuit breakers specifically rated for capacitor applications to ensure reliable protection.

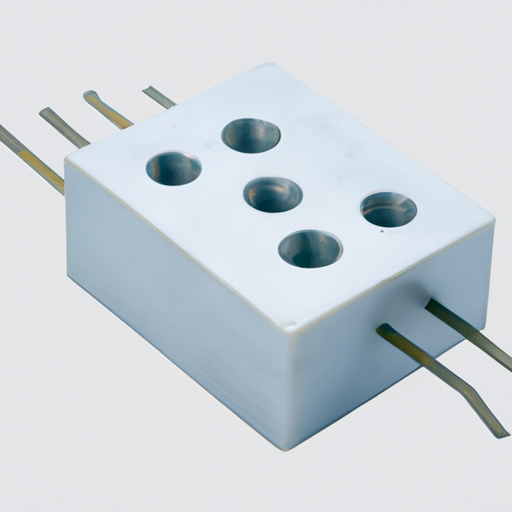

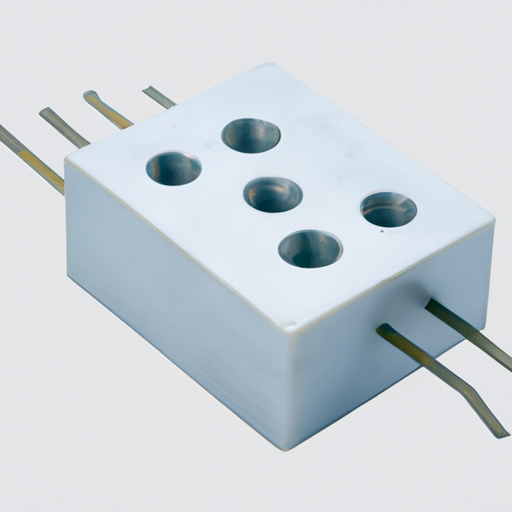

D. Reactors

Reactors are used in conjunction with capacitors to manage harmonics and improve system stability.

1. **Purpose of Reactors**: They help to limit the inrush current when capacitors are switched on and can also mitigate the effects of harmonics generated by non-linear loads.

2. **Types of Reactors**: Series reactors are connected in line with the capacitors, while parallel reactors are connected across the capacitor bank. The choice between them depends on the specific application and system requirements.

E. Control Panels

Control panels are the brains of the capacitor cabinet, providing monitoring and control functions.

1. **Overview of Control Panel Functions**: They allow operators to monitor the performance of the capacitor bank, control switching operations, and implement protective measures.

2. **Recommended Features**: Look for control panels with features such as programmable logic controllers (PLCs), digital displays, and communication interfaces for remote monitoring.

IV. Additional Components and Accessories

A. Surge Protection Devices

Surge protection devices (SPDs) are critical for protecting the capacitor cabinet from voltage spikes caused by lightning strikes or switching operations.

1. **Importance of Surge Protection**: Without adequate surge protection, capacitors and other components can be damaged, leading to costly repairs and downtime.

2. **Recommended Types**: Choose SPDs that are specifically designed for use with capacitor banks, ensuring they can handle the expected surge currents.

B. Monitoring Equipment

Monitoring equipment is essential for assessing the performance of the capacitor cabinet and ensuring optimal operation.

1. **Role of Monitoring**: Continuous monitoring allows for early detection of issues, enabling timely maintenance and reducing the risk of failures.

2. **Suggested Tools**: Consider using power quality analyzers, temperature sensors, and remote monitoring systems to keep track of the cabinet's performance.

C. Enclosures and Mounting Hardware

Proper enclosures and mounting hardware are vital for protecting the components of the capacitor cabinet from environmental factors.

1. **Importance of Proper Enclosures**: Enclosures shield the components from dust, moisture, and physical damage, ensuring longevity and reliability.

2. **Recommendations**: Look for enclosures made from durable materials such as stainless steel or fiberglass, and ensure they are rated for the specific environmental conditions of the installation site.

V. Best Practices for Component Selection

A. Assessing System Requirements

Before selecting components for a capacitor cabinet, it is essential to assess the specific requirements of the electrical system.

1. **Load Calculations and Power Factor Analysis**: Conduct thorough load calculations to determine the necessary capacitance and power factor correction needed for the application.

2. **Environmental Considerations**: Consider factors such as temperature, humidity, and exposure to corrosive elements when selecting components.

B. Compatibility and Standards

Ensuring compatibility between components and adherence to industry standards is crucial for the safe and efficient operation of capacitor cabinets.

1. **Importance of Adhering to Industry Standards**: Compliance with standards such as IEEE and IEC ensures that components are reliable and safe for use.

2. **Recommendations for Compatible Components**: Always choose components from reputable manufacturers that provide clear specifications and compatibility information.

C. Cost vs. Quality Considerations

Balancing budget constraints with the need for quality components is a common challenge in capacitor cabinet design.

1. **Balancing Budget Constraints with Quality Needs**: While it may be tempting to opt for lower-cost components, investing in quality can lead to long-term savings through reduced maintenance and increased reliability.

2. **Long-Term Investment Considerations**: Consider the total cost of ownership, including installation, maintenance, and potential downtime, when making component selections.

VI. Case Studies and Examples

A. Successful Implementations of Capacitor Cabinets

Numerous industries have successfully implemented capacitor cabinets to improve energy efficiency and reduce costs. For example, a manufacturing plant that installed a capacitor bank saw a 15% reduction in energy costs and improved power factor, leading to significant savings on utility bills.

B. Lessons Learned from Various Applications

Through various applications, it has been observed that proper sizing and selection of components are critical to achieving desired outcomes. In one case, a facility that underestimated its load requirements faced frequent capacitor failures, highlighting the importance of thorough analysis before installation.

C. Recommendations Based on Real-World Experiences

Based on real-world experiences, it is recommended to engage with experienced engineers during the design phase to ensure that all components are appropriately selected and integrated into the system.

VII. Conclusion

Selecting the right components for capacitor cabinets is crucial for optimizing performance and ensuring the reliability of electrical systems. By understanding the essential components, their functions, and best practices for selection, users can make informed decisions that lead to improved energy efficiency and reduced operational costs. As technology continues to evolve, staying informed about advancements in capacitor cabinet technology will be essential for maintaining optimal performance in electrical systems.

VIII. References

A comprehensive list of sources for further reading, including industry standards and guidelines for capacitor cabinet components, can be found in the references section. Engaging with these resources will provide additional insights and support for those looking to deepen their understanding of capacitor cabinet technology.