What is the Working Principle of Capacitor Manufacturers?

I. Introduction

Capacitors are fundamental components in the world of electronics, serving as energy storage devices that play a crucial role in various applications, from power supply circuits to signal processing. Defined as passive electrical components, capacitors store electrical energy in an electric field, which can be released when needed. Their importance in electronic devices cannot be overstated; they help stabilize voltage and power flow, filter signals, and provide timing elements in circuits. This blog post will delve into the working principles of capacitor manufacturers, exploring the intricacies of capacitor design, the manufacturing process, and the future of this essential industry.

II. Understanding Capacitors

A. Basic Components of a Capacitor

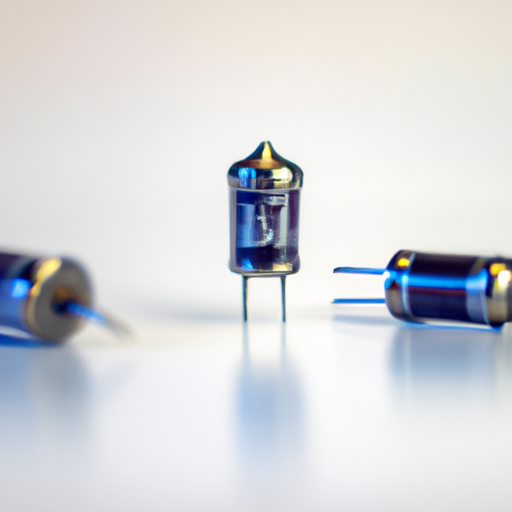

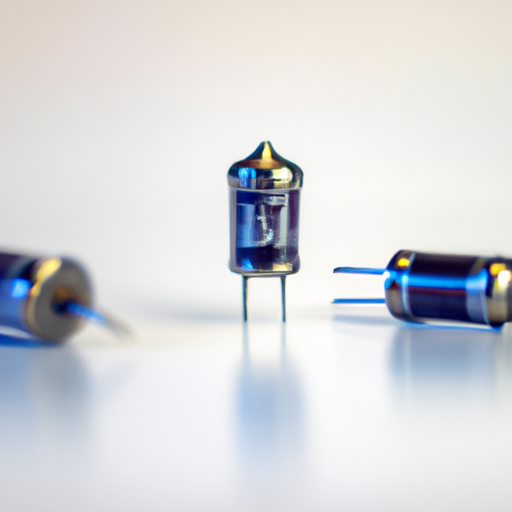

At its core, a capacitor consists of two conductive plates separated by a dielectric material. The conductive plates, typically made of metals like aluminum or tantalum, store electrical charge. The dielectric material, which can be ceramic, plastic, or electrolytic, serves to insulate the plates and increase the capacitor's ability to store charge by allowing a stronger electric field to form between them.

B. Types of Capacitors

Capacitors come in various types, each suited for specific applications:

1. **Ceramic Capacitors**: Known for their small size and reliability, ceramic capacitors are widely used in high-frequency applications.

2. **Electrolytic Capacitors**: These capacitors have a higher capacitance value and are often used in power supply circuits. They are polarized, meaning they must be connected in the correct direction.

3. **Film Capacitors**: Made from thin plastic films, these capacitors are known for their stability and low loss, making them ideal for audio and high-frequency applications.

4. **Tantalum Capacitors**: These are compact and have a high capacitance-to-volume ratio, making them suitable for space-constrained applications.

C. Key Specifications

When selecting a capacitor, several key specifications must be considered:

1. **Capacitance**: Measured in farads, capacitance indicates the amount of charge a capacitor can store.

2. **Voltage Rating**: This specification indicates the maximum voltage a capacitor can handle without breaking down.

3. **Tolerance**: This refers to the allowable deviation from the stated capacitance value, which can affect circuit performance.

III. The Manufacturing Process of Capacitors

A. Raw Material Selection

The manufacturing process begins with the careful selection of raw materials. Conductive materials, such as aluminum or tantalum, are chosen for the plates, while dielectric materials are selected based on the desired electrical properties and application requirements. The quality of these materials directly impacts the performance and reliability of the final product.

B. Production Techniques

The production of capacitors involves several key techniques:

1. **Layering and Winding**: For certain types of capacitors, such as film and electrolytic, layers of dielectric material are sandwiched between conductive plates. In the case of electrolytic capacitors, the plates are often rolled into a cylindrical shape to save space.

2. **Pressing and Sintering**: In the case of ceramic capacitors, the dielectric material is pressed into shape and then sintered at high temperatures to enhance its electrical properties.

3. **Coating and Encapsulation**: After the capacitor is assembled, it is coated or encapsulated to protect it from environmental factors and mechanical stress. This step is crucial for ensuring the longevity and reliability of the capacitor.

C. Quality Control Measures

Quality control is a vital aspect of capacitor manufacturing. Manufacturers conduct rigorous testing to ensure that each capacitor meets specified performance criteria. This includes:

1. **Testing for Capacitance and Leakage**: Capacitors are tested to verify their capacitance values and to check for any leakage current, which can indicate defects.

2. **Environmental Testing**: Capacitors are subjected to various environmental conditions, such as temperature and humidity, to ensure they can operate reliably in real-world applications.

3. **Compliance with Industry Standards**: Manufacturers must adhere to industry standards, such as those set by the International Electrotechnical Commission (IEC) and the American National Standards Institute (ANSI), to ensure safety and performance.

IV. The Role of Technology in Capacitor Manufacturing

A. Automation in Production

The capacitor manufacturing process has seen significant advancements due to automation. Automated machinery enhances precision and efficiency, reducing the likelihood of human error and increasing production rates. This technology allows manufacturers to produce capacitors at a lower cost while maintaining high quality.

B. Advanced Materials and Their Impact

The development of advanced materials has also transformed capacitor manufacturing. New dielectric materials with improved electrical properties enable the production of smaller capacitors with higher capacitance values. This miniaturization is essential for modern electronic devices, which demand compact components.

C. Innovations in Capacitor Design

Innovations in capacitor design, such as the introduction of hybrid capacitors that combine the benefits of different types, are also shaping the industry. These advancements allow for greater flexibility in applications, catering to the diverse needs of electronic devices.

V. Challenges Faced by Capacitor Manufacturers

A. Supply Chain Issues

Capacitor manufacturers face challenges related to supply chain disruptions, particularly in sourcing raw materials. Global events, such as natural disasters or geopolitical tensions, can impact the availability and cost of essential materials, affecting production timelines and pricing.

B. Environmental Regulations

As environmental concerns grow, manufacturers must navigate increasingly stringent regulations regarding waste management and the use of hazardous materials. Compliance with these regulations can add complexity and cost to the manufacturing process.

C. Competition and Market Demand

The capacitor market is highly competitive, with numerous manufacturers vying for market share. Additionally, the rapid pace of technological advancement means that manufacturers must continuously innovate to meet changing market demands and consumer preferences.

VI. Future Trends in Capacitor Manufacturing

A. Miniaturization of Capacitors

The trend toward miniaturization is expected to continue, driven by the demand for smaller and more efficient electronic devices. Manufacturers will need to develop even more compact capacitors without compromising performance.

B. Development of New Materials

Research into new dielectric materials and conductive substances will likely lead to the creation of capacitors with enhanced performance characteristics. These materials may offer improved energy density, thermal stability, and environmental resistance.

C. Sustainability Initiatives

Sustainability is becoming a key focus for capacitor manufacturers. Initiatives aimed at reducing waste, recycling materials, and using eco-friendly production processes will be essential for meeting regulatory requirements and consumer expectations.

VII. Conclusion

In conclusion, capacitors are vital components in modern electronics, and understanding the working principles of capacitor manufacturers is essential for appreciating their role in technology. From the selection of raw materials to the intricacies of the manufacturing process, each step is crucial in producing reliable and efficient capacitors. As the industry evolves, manufacturers will face challenges and opportunities that will shape the future of capacitor technology. With ongoing advancements in materials, design, and production techniques, the capacitor manufacturing landscape is poised for exciting developments that will continue to support the ever-growing demands of electronic devices.